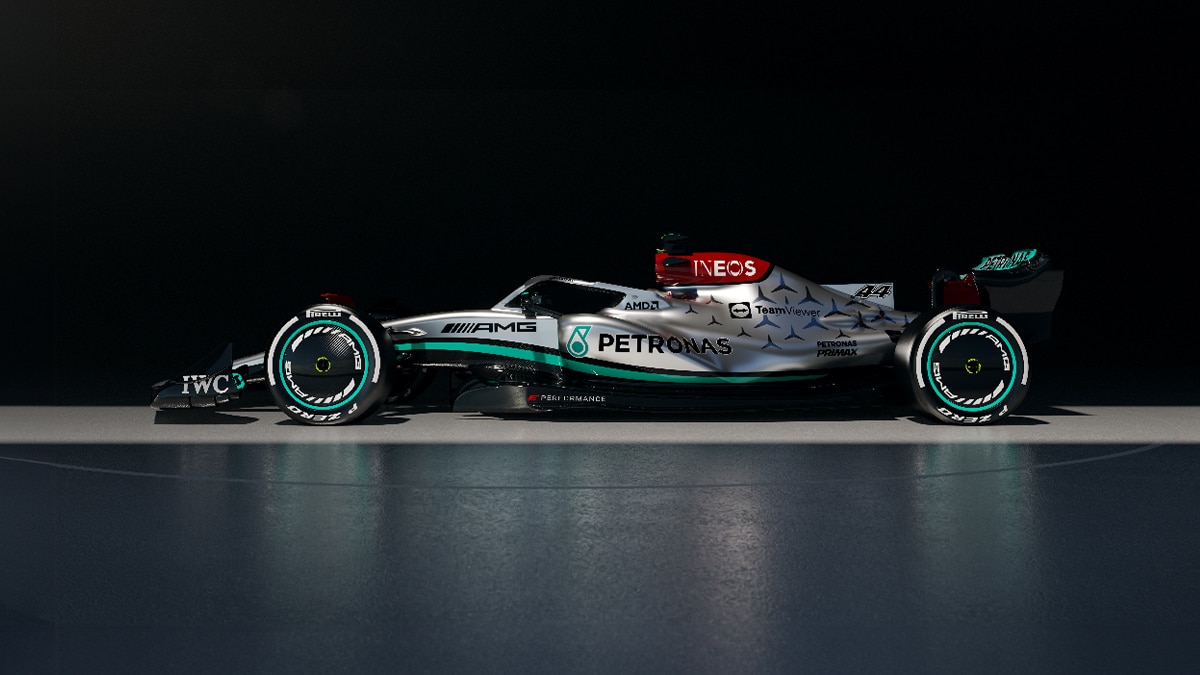

Mercedes-AMG Petronas F1 Team wins pole position with AMD EPYC™ CPUs

AMD EPYC™ processors enable the best possible aerodynamics for Formula 1 racing success.

The Mercedes-AMG Petronas F1 team has a long tradition of achievement. One of the most important reasons for this has been the groundbreaking aerodynamics of its Formula 1 cars.

Since the late 1970s, F1 teams have realized the significance of airflow, and from the very beginning optimizing this has been a computer-aided activity. This has only increased throughout the years, and now the competition on the track is mirrored by a battle in the data center, with the most effective computational analysis providing the edge. The Mercedes F1 team’s testing found that AMD EPYC™ processors could provide the advantage it needed for success.

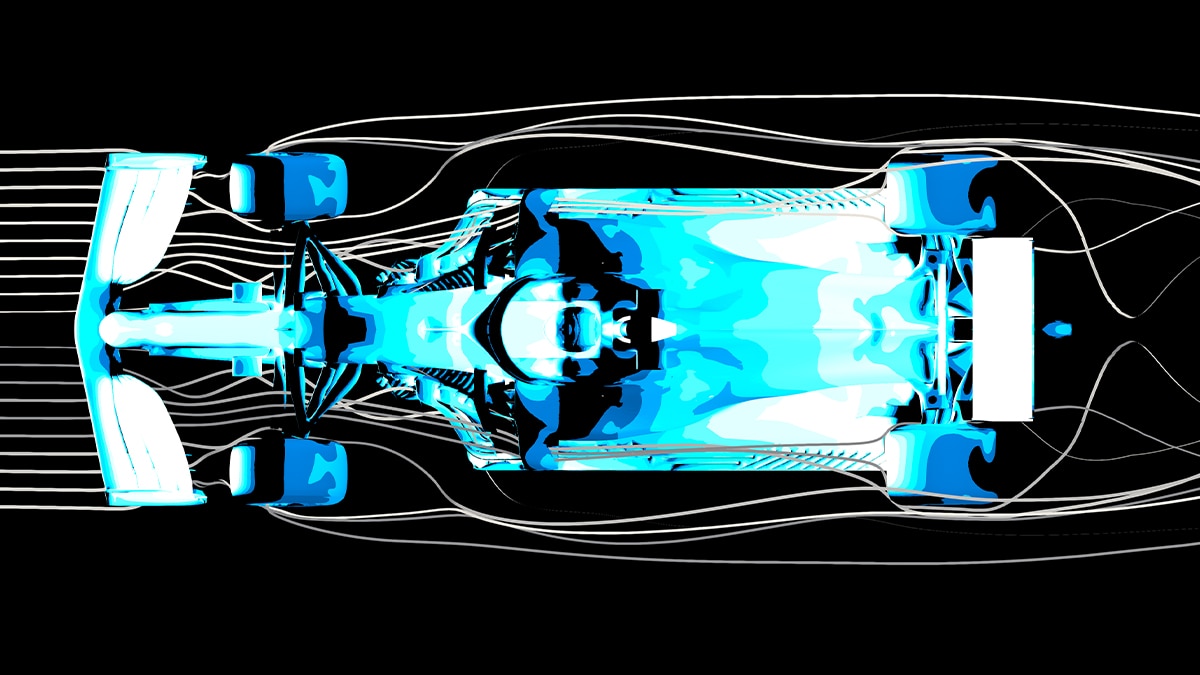

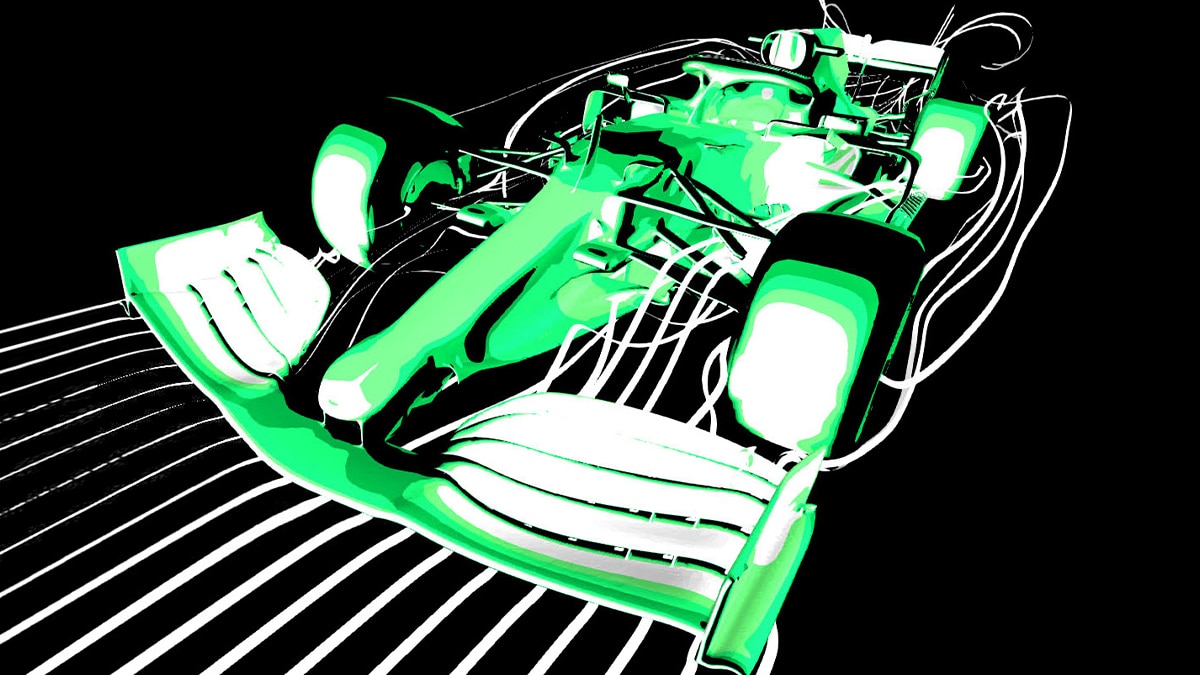

The importance of aerodynamics

“Our end goal is winning championships,” says Simon Williams, Head of Aero Development Software at Mercedes-AMG Petronas F1. “The aerodynamics of the car is one of the biggest performance differentiators.” A keystone to this is Computational Fluid Dynamics (CFD) which models and tests aerodynamic flow. “Having the best CFD on the grid is our aim. That obviously relates to the hardware that we are using.”

Over the years, the Fédération Internationale de l'Automobile (FIA) has developed an intricate framework dictating how much CFD performance and wind tunnel time F1 teams are allowed to use, so that the teams with more resources don’t obtain an insurmountable advantage. These rules continue to evolve, and whereas there was a restriction on compute power for the 2020 season, in 2021 this shifted to a limit on how many model geometries could be tested plus a cap on overall spending. From $145 million for the 2021 season, it has been reduced to $140 million in 2022 and then will be $135 million in 2023. The money spent on servers used for CFD is included in this budget, so it’s fundamentally advantageous to obtain the most processing power possible for the money spent.

“All of the capital expenditure for these systems is part of that budget now,” says Williams. This ultimately led the team to AMD processors. Williams

had been familiar with AMD’s involvement with Formula 1 for a while. “Going back to around 2012, AMD did some good work creating a custom CPU, the ‘Fangio’ chip as it was named, which was pushing the boundaries of the regulations,” he says. This was an AMD Opteron 6276 but with a limited Floating-Point specification. “It wasn't just about clock cycles.”

The new FIA regulations for 2021 shifted the focus on compute power even more. “Wind tunnel hours and computational fluid dynamics were previously both regulated to a common number, so you could bias towards wind tunnel or CFD,” says Williams. “The FIA decoupled that for 2021. The next thing they did was provide an uplift on the amount of compute we could have. The third thing was prorating it based on where your performance is in the championship, so there's a sliding scale that biases the capacity you have to develop aerodynamics.” For the 2021 season, the bottom team had 25 percent more than the top team, but for 2022 this spread will increase to 64 percent. Mercedes-AMG Petronas F1 finished top in the 2021 season, so will have the least allocation, further accentuating the team’s need for the best possible computational ability.

Optimizing compute for new regulations

Optimizing compute for new regulations “We're trying to make most of that, as well as just the raw compute,” says Williams. “There's also a regulation of how many geometries we can run in a certain period, which usually spans eight weeks. We're trying to maximize everything we can do in that period to get the most out of our CFD.” The quota amounts to around 1,800 new geometry simulations over the eight-week period. “It's about trying to maximize the work that the CFD solve can do per clock cycle.” The faster these calculations can be performed, the better.

AMD EPYC™ processors proved to be the best to achieve this. “We had new regulations coming in and were refreshing our systems,” says Williams. “Performance was the key driver of the decision making. We looked at AMD and the competitors. The CFD solve was the critical factor when running benchmarks. We needed to get this right, because we're going to be on this hardware for three years. The other element was that we have the hardware on premises, and if it takes up the whole data center then that wasn't going to be an option.”

“EPYC was the front runner in delivering the performance and space saving we needed,” continues Williams. The Mercedes F1 team chose 2nd Generation AMD EPYC™ processors to replace the three-and-a-half-year-old system it had from another vendor. “We gained a 20 percent efficiency improvement on the old system. This is a big step because we're usually looking at one or two percent gains. The new system is allowing us to focus our effort on aerodynamic performance. Reliability has been great too. If we miss even a few hours that puts us on the back foot, so it's important that these systems are robust and reliable. This is something that EPYC has delivered. The time scales are so short from initial idea, to CFD, to testing in the tunnel, and then into the car. It could be measured in weeks. The fact that we've been able to deliver consistently over the year has been key.”

Ready for the next F1 season’s challenges

AMD EPYC™ processors will help Mercedes F1 face the future as competitively as possible. “There's a huge upheaval in the technical regulations coming for 2022,” says Williams. “Because it's such a big change we need to get as early a start as we can on our car. The AMD EPYC servers have enabled us to run a lot more work in parallel. Aerodynamicists, if they get a result back during the day, they can do another design and do a second run overnight. When they return in the morning, they will have completed two iterations, rather than one. You’ve got to have the right hardware to do that.”

“One of the biggest impacts we're going to have will be the regulation on how many geometries we can try,” concludes Williams. “That's going to reduce as well, depending on where we finish. If we finish at the top of the constructors, we get fewer geometries through the system. That's going to change how we approach the work. It's been great going to this new hardware. The performance has been delivered as we benchmarked. The servers have been very reliable. They have given us a platform delivering aerodynamic performance day after day at the highest possible level. AMD EPYC processors have been a critical part of giving us a competitive edge over the others on the grid. It has been essential for winning races and championships. I can't stress enough how important the fast turnaround is. It's been great having AMD help us achieve that. AMD has helped us meet the goal of faster iterative performance and cutting the time in half, thanks to 20 percent faster compute.”

About the Customer

The Mercedes-AMG Petronas F1 Team, based in Brackley, England. Mercedes’ Formula 1 history began in 1954, with driver Juan Manual Fangio winning two Championships. After leaving the sport in 1955, Mercedes returned in 1994 as an engine supplier, winning one Constructor’s and three Driver’s titles with McLaren. Mercedes became a team brand in 2010 after the purchase of Brawn GP. Since then, Mercedes has collected 124 race wins, 264 podiums, eight Constructors’ Championships, and nine Drivers’ Championships. For more information visit mercedesamgf1.com/en.

Case Study Profile

- Industry:

Motor racing - Challenges:

Provide the greatest compute power within the stringent F1 CFD regulations alongside the most efficient space usage - Solution:

Deploy 2nd Gen AMD EPYC™ CPU-powered servers - Results:

20 percent faster performance than previous systems, allowing twice as many design iterations per day - AMD Technology at a Glance:

2nd Gen AMD EPYC™ processors