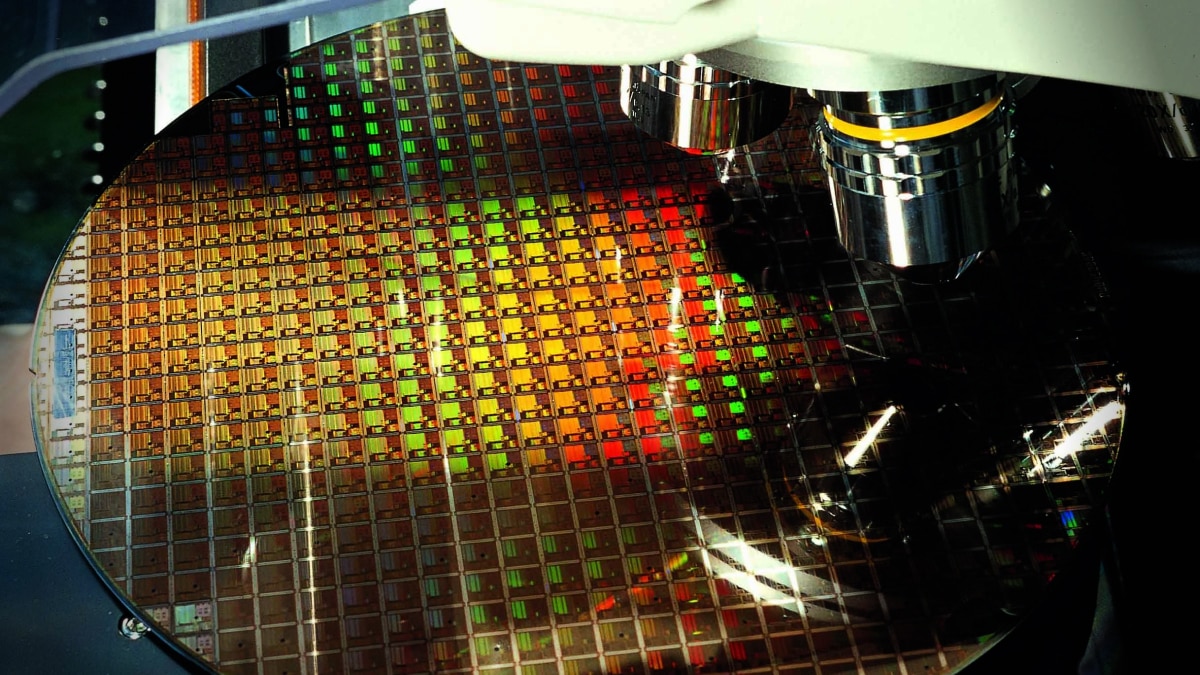

TSMC enables semiconductor fabrication expansion with AMD

Better cost-performance with fewer servers by deploying 4th Gen AMD EPYC processors

TSMC is already the leading foundry of semiconductor wafers in the world, but the foundry giant has bold plans for further expansion. This will require even more computational power to run its production, research, development, and general IT infrastructure. AMD EPYC™ processors were already playing a key role for TSMC, but 4th Gen AMD EPYC CPUs have provided the additional increase in capabilities required for the company to achieve its growth goals.

“TSMC is expanding very quickly,” said Simon Wang, director of Infrastructure and Communication Services Division at TSMC. “We are expanding our global manufacturing footprint and have new fabrication plants being built in Taiwan, Japan, Germany, and the U.S. That means we are going to require a lot of computing power for fab production, research and development simulation, and business operation.”

For its upgraded infrastructure, TSMC wanted to maximize computing performance while limiting power consumption. “When we evaluate servers and storage, we look at the computing performance per unit of power consumed, the space it takes, and the cost,” said Wang. “Our workloads roughly fall into three categories. The first one is for automated fab production. The second is for research and development including simulation and design, working with Cadence and Synopsys Electronic Design Automation. Mask-making also requires a lot of computing power, as does pathfinding. We are also searching for new materials and new technology for next-generation products. The third category is for business operation, supporting units like taking orders, HR, and legal.”

Empowering TSMC across three workload types

“Most of our fab automation is CPU based, using a Linux platform with virtual machines or Kubernetes,” said Wang. “This is supported by a large quantity of storage. For R&D, we use CPUs with GPUs. In the third category of business operation, the quantity is limited compared with the other two because these are systems used by our supporting units and they mostly use CPU servers.”

Although TSMC is the manufacturing partner for the AMD EPYC processor range, internal regulations meant that Wang had no special knowledge of forthcoming AMD products, although his experience with previous generations had been very positive. Knowledge of the roadmap came from the AMD country manager in Taiwan, but Wang still needed to ensure the new generation would serve TSMC’s requirements. “The IT department has an additional responsibility to prove that our products are good,” he said. “I wanted to prove that the latest AMD processors produced by TSMC have better performance at lower power consumption than the previous generation.”

“The IT department first defines the configuration that we want based on workload,” said Wang. “We define the specifications for the CPU, clock rate, memory, and solid-state drive (SSD). Every year we define five to seven models, which we send to the vendors and ask for their feedback. It's an open bidding process where we decide the ultimate vendor. We are vendor-agnostic. We decide on the vendor based on pricing, performance, and power efficiency.”

Better cost-performance with AMD EPYC CPUs

“For the 4th Gen AMD EPYC rollout, we considered two options: a single-socket CPU with more cores or dual CPUs with fewer cores each but the same overall total,” said Wang. “We evaluated the cost performance of these two configurations. Originally, we thought that two CPUs with fewer cores would come out better, but one socket with more cores did.”

“For performance testing, we use generic tools available on the market,” said Wang. “In addition to those tools, we also use our pre-production environment, to see how the workload would perform and to see the response time. That was tested in our fab production and the R&D design center as well. In addition to testing performance and power consumption, we also test the server operability, which includes auto provisioning, so we work with the vendors for this.”

“Compared to the previous generation, we found that 4th Gen AMD EPYC CPUs delivered more than a 30 percent gain in cost performance,” said Wang. “Migration was very easy for fab production and automation. The IT department had a smooth transition, too. The only thing that we spent more time on was the R&D mask making because this process requires very high precision, but in the end, the team certified the AMD CPUs.”

“In January of this year we were looking at the total number of CPUs that we bought last year and the plans for this year,” said Wang. “We realized that by deploying 4th Gen AMD EPYC CPUs, we could buy fewer servers while increasing the computing performance by 30 to 40 percent. So migration was something that we must do.” The increased performance per server also means that TSMC needs less space in the data center to deliver the same performance.

Better performance, lower cost, reduced power

Power consumption was also reduced thanks to the server density. “Computing performance has increased by 10 to 20 percent per watt of power consumed,” said Wang. “The greater number of cores per CPU and support for more memory are the best features of AMD processors. Cost performance per socket is better too. For the same number of cores, we found that one socket performs almost 10 percent better and the cost is lower. In our experience, the energy efficiency is more than 30 percent better when running 4th Gen AMD EPYC processors. With the most advanced TSMC fab, more than 90 percent of the workload now runs on 4th Gen AMD EPYC CPUs. The TSMC IT department now has close to 20,000 servers powered by AMD EPYC CPUs across our three workload areas, with 6,600 already powered by 4th Gen AMD EPYC CPUs.”

TSMC is using 4th Gen AMD EPYC 9124 and 9354P processors for its Kubernetes general worker nodes, 9254 for Kubernetes database nodes, and 9254 or 9454P for Cassandra nodes. “We will continue to deploy AMD CPUs in our data centers because in our experience they are better in terms of cost, performance, and computing power per watt,” said Wang. “More than 90 percent of the X86 servers we are purchasing now use 4th Gen AMD EPYC CPUs. We will keep a close eye on the next-generation products from AMD.”

“It has always been the policy of the TSMC IT department that we use the latest products to enhance the performance of our data centers,” said Wang. “AMD products are ideal for cloud-native environments because of the core density and support for large amounts of memory. It’s ideal for multi-tenant and multi-tasking environments. The cost is not high, either.”

“We have a very smooth collaboration partnership with AMD,” concludes Wang. “These products meet our performance and cost requirements very well. We are looking forward to the latest GPUs from AMD, including the Instinct MI300X with faster speed and higher performance. Then we can deploy AMD technology to even more of our workloads.”

About the Customer

TSMC pioneered the pure-play foundry business model when it was founded in 1987 and has been the world’s leading dedicated semiconductor foundry ever since. The Company supports a thriving ecosystem of global customers and partners with the industry’s leading process technologies and portfolio of design enablement solutions to unleash innovation for the global semiconductor industry. With global operations spanning Asia, Europe, and North America, TSMC serves as a committed corporate citizen around the world. TSMC deployed 288 distinct process technologies and manufactured 11,895 products for 528 customers in 2023 by providing the broadest range of specialty and advanced packaging technology services. The Company is headquartered in Hsinchu, Taiwan. For more information, please visit tsmc.com.

Case Study Profile

- Industry:

Semiconductor manufacturing - Challenges:

Improving data center cost-performance to facilitate international growth - Solution:

Deploy 4th Gen AMD EPYC™ processors across fab production, research and development, and business operations - Results:

Up to 40 percent better performance using fewer servers and less power - AMD Technology at a Glance:

4th Gen AMD EPYC processors - Technology Partners: