AMD 2023 Manufacturing Supplier Audit Performance Data

Partnering with our suppliers to advance human rights, environmental sustainability, and supply chain resilience.

Overview

AMD is a full member of the Responsible Business Alliance (RBA). AMD adopts the RBA Code of Conduct as our Supplier Code of Conduct, and its standards span labor, health and safety, environment, ethics, and management systems. To help verify their compliance in 2023, 29 AMD Manufacturing Suppliers were audited by a third-party approved Responsible Business Alliance (RBA) auditor. “Manufacturing Suppliers” are defined as suppliers that AMD buys from directly and that provide direct materials and/or manufacturing services to AMD.

The average initial RBA initial Validated Assessment Program (VAP) audit score for AMD Manufacturing Suppliers in 2023 was 15% better than the overall RBA average over the same time period.

In 2023, 44 initial VAP audits were conducted at Manufacturing Supplier factories in the AMD supply chain. Most of these audits took place in Greater China, where we have the highest number of suppliers. Additionally, 87% of the AMD these factories audited in 2023 obtained VAP Recognition , which means the RBA recognized them for their commitment to social and environmental responsibility1. At the end of 2023, the top 75% of these suppliers in our supply chain, by spend, had the highest level of VAP recognition status. AMD wafer suppliers continue to score 200 – the highest RBA audit score possible.

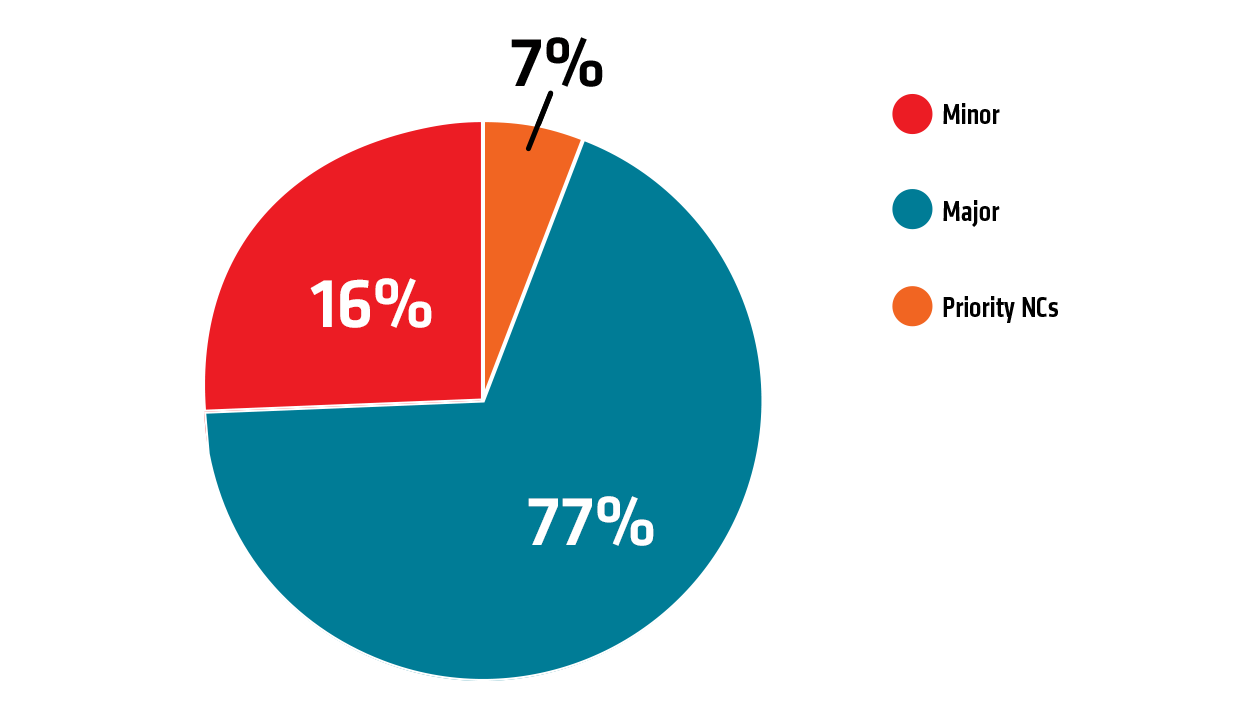

The VAP audit categorizes nonconformances (NCs) or findings by severity, as “Minor,” “Major,” or “Priority.”

In 2023, 77% of all NCs in these audits were classified as Major NCs. All affected suppliers were required to complete a corrective action plan for the issues identified. Major NCs2 included:

- Supplier responsibility

- Emergency preparedness

- Working hours

- Occupational safety

Percentage of Non-comformances by Rating (2023)

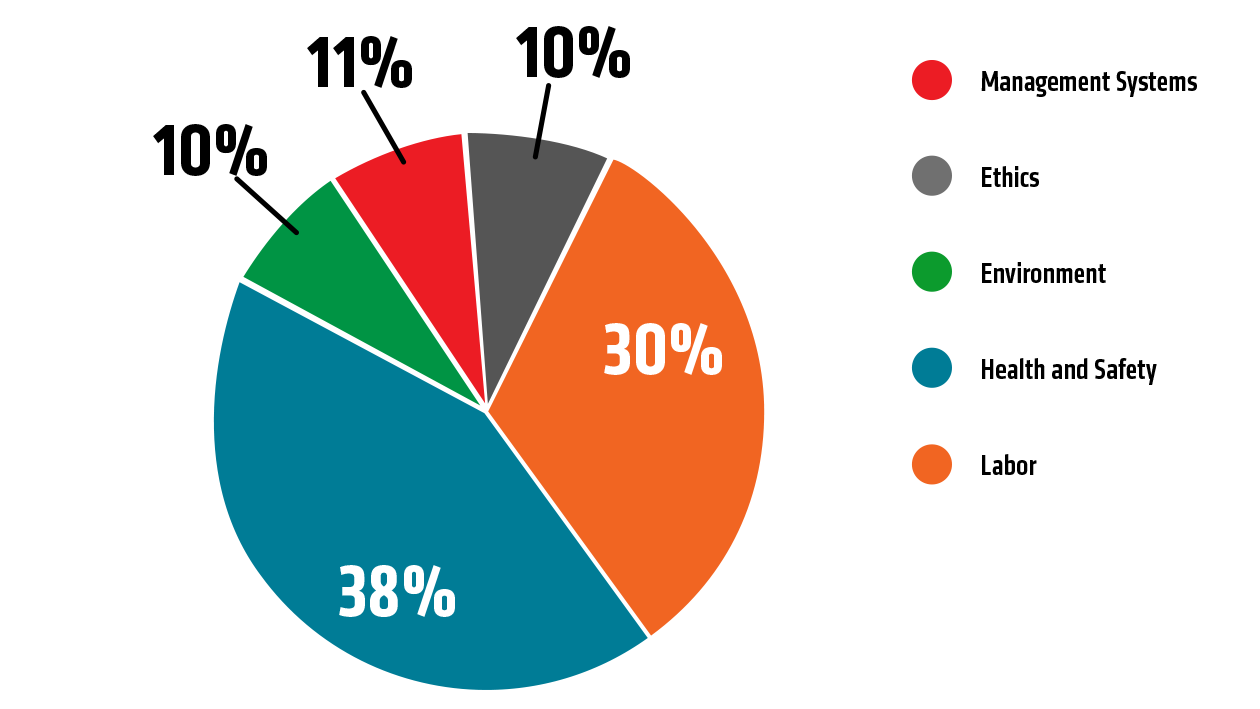

Across the five sections of the VAP, the highest number findings were in the health and safety section (specifically emergency preparedness).

Remediation

All three finding categories have specified periods during which the audited facility must remedy the findings and implement systems to prevent reoccurrences. AMD Manufacturing Suppliers are required to manage and close a Corrective Action Plan (CAP) in accordance with the RBA VAP Protocol. If these suppliers are not able to meet AMD requirements, AMD executives are notified for appropriate action.

Measuring Effectiveness

We take a continuous improvement approach to supporting our Manufacturing Suppliers to improve their compliance to the Supplier Code of Conduct. Among the suppliers that had an initial and closure audit in 2023, the audit score increased by 25% on average from initial audit to closure audit3. Our Manufacturing Suppliers are required to score at least a 160 on the VAP audit and close any Priority findings. Several of the suppliers that were not required to have a closure audit opted to have one and increased their scores, in some cases from VAP recognition level silver to platinum.

Audits Conducted by Location (2023)

| Region/Country | # Initial Audits | # Closure Audits4 | Priority Closure Audit |

| Greater China | 27 | 10 | 2 |

| Czech Republic | 1 | 0 | 0 |

| Germany | 1 | 0 | 0 |

| Japan | 3 | 1 | 0 |

| Malaysia | 2 | 3 | 0 |

| Philippines | 2 | 0 | 0 |

| Singapore | 1 | 0 | 0 |

| South Korea | 3 | 2 | 0 |

| Thailand | 1 | 0 | 0 |

| United States | 3 | 0 | 0 |

| TOTAL | 44 | 14 | 2 |

All nonconformances (NCs) by section of the AMD Supplier Code of Conduct (2023)

Labor

Labor represented 30% of all NCs in these audits in 2023, down from 40% the previous year, with improvement in the areas of working hours and freely chosen employment. Some NCs in the category of freely chosen employment were related to workers paying fees prohibited by the AMD Supplier Code of Conduct. In these cases, we require the supplier to provide evidence that the workers were reimbursed in order to close the finding. In other cases, suppliers lacked sufficient policies or management practices to prevent the risk of forced labor.

Health and Safety

Approximately 38% of all NCs in these audits in 2023 were in the area of health and safety (down from 45% in 2022). The majority of the issues related to emergency preparedness – specifically effective emergency exits. These suppliers took immediate containment action within the RBA timeline and completed closure audits where required.

We continue to take proactive steps to remind all of our Manufacturing Suppliers of our expectations around emergency preparedness.

2023 Manufacturing Supplier Audit Results

Nonconformances by Type, Initial Audits (2023)5

| Priority | Major | Minor | Total | Percentage | |

| Labor | 6 | 45 | 8 | 59 | 30% |

| Freely chosen employment | 2 | 4 | 0 | 6 | |

| Child labor avoidance | 1 | 1 | 2 | 4 | |

| Working hours | 2 | 10 | 1 | 13 | |

| Wages and benefits | 1 | 6 | 2 | 9 | |

| Control processes | 0 | 10 | 2 | 12 | |

| Performance review and continuous improvement | 0 | 7 | 1 | 8 | |

| Risk assessment | 0 | 4 | 0 | 4 | |

| Communications | 0 | 2 | 0 | 2 | |

| Non-discrimination | 0 | 1 | 0 | 1 | |

| Health and safety | 5 | 54 | 16 | 75 | 38% |

| Occupational safety | 0 | 11 | 1 | 12 | |

| Emergency preparedness | 3 | 13 | 5 | 21 | |

| Occupational injury and illness | 0 | 2 | 3 | 5 | |

| Machine safeguarding | 0 | 0 | 1 | 1 | |

| Food, sanitation, and housing | 1 | 2 | 2 | 5 | |

| Health and safety communication | 0 | 1 | 0 | 1 | |

| Control processes | 0 | 9 | 4 | 13 | |

| Risk assessment | 0 | 3 | 0 | 3 | |

| Communications | 0 | 2 | 0 | 2 | |

| Performance review and continuous improvement | 0 | 6 | 0 | 6 | |

| Risk assessment | 0 | 1 | 0 | 1 | |

| Food, sanitation, and housing | 1 | 2 | 0 | 3 | |

| Industrial hygiene | 0 | 2 | 0 | 2 | |

| Environment | 0 | 18 | 1 | 19 | 10% |

| Environmental permits and reporting | 0 | 1 | 0 | 1 | |

| Hazardous substances | 0 | 2 | 0 | 2 | |

| Solid waste | 0 | 1 | 1 | 2 | |

| Performance review and continuous improvement | 0 | 3 | 0 | 3 | |

| Risk assessment | 0 | 1 | 0 | 1 | |

| Control processes | 0 | 4 | 0 | 4 | |

| Communications | 0 | 2 | 0 | 2 | |

| Risk Assessment | 0 | 2 | 0 | 2 | |

| Ethics | 3 | 14 | 3 | 20 | 10% |

| No improper advantage | 1 | 0 | 2 | 3 | |

| Performance review and continuous improvement | 0 | 6 | 1 | 7 | |

| Protection of identity and non-retaliation | 1 | 0 | 0 | 1 | |

| Risk assessment | 0 | 4 | 0 | 4 | |

| Control processes | 1 | 2 | 0 | 3 | |

| Communications | 0 | 2 | 0 | 2 | |

| Management system | 0 | 19 | 3 | 22 | 11% |

| Supplier responsibility | 0 | 13 | 2 | 15 | |

| Legal and customer requirements | 0 | 1 | 1 | 2 | |

| Audits and assessments | 0 | 1 | 0 | 1 | |

| Materials restrictions | 0 | 2 | 0 | 2 | |

| Responsible sourcing of minerals | 0 | 2 | 0 | 2 | |

| Grand Total | 195 | 100% |

Nonconformances by Location, Initial Audits (2023)

| Location / Category | A) Labor | B) Health & Safety | C) Environment | D) Ethics | E) Management Systems | Grand Total |

| Greater China | 23 | 29 | 2 | 1 | 5 | 60 |

| Czech Republic | 13 | 13 | 4 | 8 | 6 | 44 |

| Japan | 1 | 0 | 0 | 1 | 1 | 3 |

| Malaysia | 4 | 7 | 1 | 1 | 1 | 14 |

| Philippines | 0 | 3 | 0 | 0 | 0 | 3 |

| Singapore | 1 | 0 | 0 | 0 | 0 | 2 |

| South Korea | 1 | 5 | 1 | 0 | 0 | 7 |

| Thailand | 1 | 0 | 0 | 1 | 1 | 3 |

| United States | 15 | 18 | 11 | 8 | 7 | 59 |

2022 Manufacturing Supplier Audit Results

Nonconformances by Type, Initial Audits (2022)

| Priority | Major | Minor | Total | Percentage | |

| Labor | 53 | 40% | |||

| Freely chosen employment | 1 | 10 | 4 | 15 | |

| Young workers | 0 | 0 | 1 | 1 | |

| Working hours | 0 | 21 | 3 | 24 | |

| Wages and benefits | 0 | 9 | 1 | 10 | |

| Humane treatment | 0 | 0 | 0 | 0 | |

| Non-discrimination | 0 | 2 | 1 | 3 | |

| Freedom of association | 0 | 0 | 0 | 0 | |

| Health and safety | 60 | 45% | |||

| Occupational safety | 0 | 8 | 4 | 12 | |

| Emergency preparedness | 4 | 13 | 6 | 23 | |

| Occupational injury and illness | 0 | 8 | 1 | 9 | |

| Industrial hygiene | 0 | 0 | 1 | 1 | |

| Physically demanding work | 0 | 1 | 1 | 2 | |

| Machine safeguarding | 0 | 1 | 0 | 1 | |

| Food, sanitation, and housing | 3 | 7 | 1 | 11 | |

| Health and safety communication | 0 | 1 | 0 | 1 | |

| Environment | 9 | 7% | |||

| Environmental permits and reporting | 0 | 1 | 0 | 1 | |

| Pollution prevention and resource reduction | 0 | 0 | 0 | 0 | |

| Hazardous substances | 0 | 3 | 2 | 5 | |

| Solid waste | 0 | 0 | 0 | 0 | |

| Air emissions | 0 | 0 | 0 | 0 | |

| Materials restrictions | 0 | 0 | 1 | 1 | |

| Water management | 0 | 1 | 0 | 1 | |

| Energy consumption and greenhouse gas emissions | 0 | 0 | 1 | 1 | |

| Ethics | 2 | 1% | |||

| Business integrity | 0 | 0 | 0 | 0 | |

| No improper advantage | 0 | 0 | 1 | 1 | |

| Disclosure of information | 0 | 0 | 0 | 0 | |

| Intellectual property | 0 | 0 | 0 | 0 | |

| Fair business, advertising, and competition | 0 | 0 | 0 | 0 | |

| Protection of identity and non-retaliation | 0 | 0 | 0 | 0 | |

| Responsible sourcing of minerals | 0 | 1 | 0 | 1 | |

| Privacy | 0 | 0 | 0 | 0 | |

| Management system | 10 | 7% | |||

| Company commitment | 0 | 0 | 0 | 0 | |

| Management accountability and responsibility | 0 | 0 | 0 | 0 | |

| Legal and customer requirements | 2 | 0 | 0 | 2 | |

| Risk assessment and risk management | 0 | 0 | 0 | 0 | |

| Improvement objectives | 0 | 1 | 0 | 1 | |

| Training | 0 | 0 | 0 | 0 | |

| Communication | 0 | 0 | 0 | 0 | |

| Worker feedback and participation | 0 | 1 | 0 | 1 | |

| Audits and assessments | 0 | 0 | 0 | 0 | |

| Corrective action process | 0 | 0 | 0 | 0 | |

| Documentation and records | 0 | 0 | 0 | 0 | |

| Supplier responsibility | 0 | 3 | 3 | 6 | |

| TOTAL | 134 | 100% |

Nonconformances by Location, Initial Audits (2022)

| Location / Category | A) Labor | B) Health & Safety | C) Environment | D) Ethics | E) Management Systems | Grand Total |

| Greater China | 39 | 34 | 7 | 1 | 4 | 85 |

| Japan | 6 | 12 | 2 | 4 | 24 | |

| Malaysia | 3 | 7 | 1 | 11 | ||

| Singapore | 3 | 1 | 1 | 5 | ||

| South Korea | 2 | 6 | 1 | 9 |

2021 Manufacturing Supplier Audit Results

Non-conformances by Type, Initial Audits (2021)

| Priority |

Major |

Minor |

Total | Percentage | |

| Labor | 39 | 39.39% | |||

| Freely chosen employment | 1 | 8 | 6 | 15 | |

| Young workers | 0 | 0 | 0 | 0 | |

| Working hours | 0 | 16 | 0 | 16 | |

| Wages and benefits | 0 | 6 | 1 | 7 | |

| Humane treatment | 0 | 0 | 0 | 0 | |

| Non-discrimination | 0 | 0 | 1 | 1 | |

| Freedom of association | 0 | 0 | 0 | 0 | |

| Health and safety | 35 | 35.35 | |||

| Occupational safety | 0 | 7 | 1 | 8 | |

| Emergency preparedness | 2 | 7 | 7 | 16 | |

| Occupational injury and illness | 0 | 2 | 0 | 2 | |

| Industrial hygiene | 0 | 0 | 0 | 0 | |

| Physically demanding work | 0 | 0 | 0 | 0 | |

| Machine safeguarding | 0 | 0 | 2 | 2 | |

| Food, sanitation, and housing | 1 | 4 | 0 | 5 | |

| Health and safety communication | 0 | 0 | 2 | 2 | |

| Environment | 5 | 5.05% | |||

| Environmental permits and reporting | 0 | 0 | 0 | 0 | |

| Pollution prevention and resource reduction | 0 | 0 | 0 | 0 | |

| Hazardous substances | 0 | 4 | 0 | 4 | |

| Solid waste | 0 | 0 | 0 | 0 | |

| Air emissions | 0 | 0 | 0 | 0 | |

| Materials restrictions | 0 | 0 | 1 | 1 | |

| Water management | 0 | 0 | 0 | 0 | |

| Energy consumption and greenhouse gas emissions | 0 | 0 | 0 | 0 | |

| Ethics | 4 | 4.04% | |||

| Business integrity | 0 | 0 | 0 | 0 | |

| No improper advantage | 0 | 0 | 2 | 2 | |

| Disclosure of information | 0 | 0 | 0 | 0 | |

| Intellectual property | 0 | 0 | 0 | 0 | |

| Fair business, advertising, and competition | 0 | 0 | 0 | 0 | |

| Protection of identity and non-retaliation | 0 | 0 | 1 | 1 | |

| Responsible sourcing of minerals | 0 | 1 | 0 | 1 | |

| Privacy | 0 | 0 | 0 | 0 | |

| Management system | 16 | 16.16% | |||

| Company commitment | 0 | 0 | 0 | 0 | |

| Management accountability and responsibility | 0 | 3 | 1 | 4 | |

| Legal and customer requirements | 0 | 0 | 1 | 1 | |

| Risk assessment and risk management | 0 | 0 | 0 | 0 | |

| Improvement objectives | 0 | 0 | 0 | 0 | |

| Training | 0 | 0 | 1 | 1 | |

| Communication | 0 | 0 | 0 | 0 | |

| Worker feedback and participation | 0 | 0 | 0 | 0 | |

| Audits and assessments | 0 | 2 | 0 | 2 | |

| Corrective action process | 0 | 0 | 0 | 0 | |

| Documentation and records | 0 | 0 | 0 | 0 | |

| Supplier responsibility | 2 | 5 | 1 | 8 | |

| TOTAL | 99 | 100% |

Non-conformances by Location, Initial Audits (2021)

| Location / Category | Labor | Health and safety | Environment | Ethics | Management systems | Total |

| Germany | 0 | 0 | 0 | 0 | 0 | 0 |

| Greater China | 28 | 13 | 2 | 0 | 5 | 48 |

| Japan | 4 | 4 | 0 | 2 | 3 | 13 |

| Malaysia | 3 | 1 | 0 | 0 | 1 | 5 |

| Philippines | 0 | 1 | 0 | 0 | 0 | 1 |

| Singapore | 1 | 2 | 0 | 0 | 0 | 3 |

| South Korea | 2 | 15 | 1 | 2 | 6 | 26 |

| Thailand | 1 | 0 | 1 | 0 | 1 | 3 |

| United States | 0 | 0 | 0 | 0 | 0 | 0 |

2020 Manufacturing Supplier Audit Results

Non-conformances by Type, Initial Audits (2020)

| Priority | Major | Minor | Total | Percentage | |

| Labor | 17 | 46.0% | |||

| Freely chosen employment | 0 | 1 | 0 | 1 | |

| Young workers | 0 | 0 | 0 | 0 | |

| Working hours | 1 | 11 | 0 | 12 | |

| Wages and benefits | 0 | 4 | 0 | 4 | |

| Humane treatment | 0 | 0 | 0 | 0 | |

| Non-discrimination | 0 | 0 | 0 | 0 | |

| Freedom of association | 0 | 0 | 0 | 0 | |

| Health and safety | 16 | 43.2% | |||

| Occupational safety | 0 | 3 | 0 | 3 | |

| Emergency preparedness | 1 | 3 | 2 | 6 | |

| Occupational injury and illness | 0 | 1 | 2 | 3 | |

| Industrial hygiene | 0 | 1 | 0 | 1 | |

| Physically demanding work | 0 | 0 | 0 | 0 | |

| Machine safeguarding | 0 | 0 | 1 | 1 | |

| Food, sanitation and housing | 0 | 1 | 1 | 2 | |

| Health and safety communication | 0 | 0 | 0 | 0 | |

| Environment | 0 | ||||

| Environmental permits and reporting | 0 | 0 | 0 | 0 | |

| Pollution prevention and resource reduction | 0 | 0 | 0 | 0 | |

| Hazardous substances | 0 | 0 | 0 | 0 | |

| Solid waste | 0 | 0 | 0 | 0 | |

| Air emissions | 0 | 0 | 0 | 0 | |

| Materials restrictions | 0 | 0 | 0 | 0 | |

| Water management | 0 | 0 | 0 | 0 | |

| Energy consumption and greenhouse gas emissions | 0 | 0 | 0 | 0 | |

| Ethics | 1 | 2.7% | |||

| Business integrity | 0 | 0 | 0 | 0 | |

| No improper advantage | 0 | 0 | 1 | 1 | |

| Disclosure of information | 0 | 0 | 0 | 0 | |

| Intellectual property | 0 | 0 | 0 | 0 | |

| Fair business, advertising, and competition | 0 | 0 | 0 | 0 | |

| Protection of identity and non-retaliation | 0 | 0 | 0 | 0 | |

| Responsible sourcing of minerals | 0 | 0 | 0 | 0 | |

| Privacy | 0 | 0 | 0 | 0 | |

| Management system | 3 | 8.1% | |||

| Company commitment | 0 | 0 | 0 | 0 | |

| Management accountability and responsibility | 0 | 0 | 0 | 0 | |

| Legal and customer requirements | 0 | 0 | 1 | 1 | |

| Risk assessment and risk management | 0 | 0 | 0 | 0 | |

| Improvement objectives | 0 | 0 | 1 | 1 | |

| Training | 0 | 0 | 0 | 0 | |

| Communication | 0 | 0 | 0 | 0 | |

| Worker feedback and participation | 0 | 0 | 0 | 0 | |

| Audits and assessments | 0 | 0 | 0 | 0 | |

| Corrective action process | 0 | 0 | 0 | 0 | |

| Documentation and records | 0 | 0 | 0 | 0 | |

| Supplier responsibility | 0 | 0 | 1 | 1 | |

| TOTAL | 37 | 100.0% |

Non-conformances by Location, Initial Audits (2020)

| Location | Labor | Health and safety | Environment | Ethics | Management systems | Total |

| Greater China | 17 | 13 | 0 | 1 | 3 | 34 |

| Singapore | 0 | 0 | 0 | 0 | 0 | 0 |

| South Korea | 0 | 3 | 0 | 0 | 0 | 3 |

| United States | 0 | 0 | 0 | 0 | 0 | 0 |

Footnotes

- Data includes all AMD Manufacturing Suppliers with eligible VAP Recognition Program data in 2020-2022. VAPs are valid for two years.

- Data represents global rates of all NCs of sites audited in the calendar year.

- Data includes all initial and closure audits that took place in the calendar year.

- A closure audit verifies whether findings from a previous audit have been addressed and not all findings require a closure audit.

- Data is from full, initial VAP audits conducted in the calendar year. AMD aggregates all nonconformances (NCs) across all audits to determine NCs by RBA category.

- Data includes all AMD Manufacturing Suppliers with eligible VAP Recognition Program data in 2020-2022. VAPs are valid for two years.

- Data represents global rates of all NCs of sites audited in the calendar year.

- Data includes all initial and closure audits that took place in the calendar year.

- A closure audit verifies whether findings from a previous audit have been addressed and not all findings require a closure audit.

- Data is from full, initial VAP audits conducted in the calendar year. AMD aggregates all nonconformances (NCs) across all audits to determine NCs by RBA category.